Ing. Tridico Esther Elisabetta – Rossano, 29 April 2020.

Bio-Binder Bitumen free

INTRODUCTION

We are in the year 2020. We are living in a century in which environmental disasters, pollution, climate change are a tangible problem that is causing concern to the world’s population. There have been many precautionary initiatives to end the destruction of our planet, starting with the improvement of our lifestyles; we have all been invited to lead healthy, ethically correct lives, paying particular attention to energy saving, waste recycling and reducing waste and waste materials. Hence the need to extend the life cycle of raw materials and to consider waste not as something useless, but as a new resource.

In this regard, I took part in the study of an eco-sustainable binder, starting from the use of materials from industrial waste elements and the food chain. The study concluded with a rheological analysis of the biobinder in order to determine its validity with regard to the physical-mechanical performance that would make it suitable for use in road pavements.

EXPERIMENTATION

For bituminous conglomerate, reference is made to a mixture of stone aggregates (such as gravel, grit and sand), bituminous binder and filler, (i.e. the thinnest part, less than 0.063 mm in size) which has the function of adding to the mixture, creating with the binder a real mastic capable of holding the aggregates together.

In the field of road construction, a first step towards environmental sustainability has been taken with the packaging procedures, which have seen, over time, a drastic drop in temperatures from 170° for Asphalt Hot Mixes, to 110° for Asphalt Warm Mixes up to 30° for Asphalt Cold Mixes…

In the thesis work, for the formulation of an innovative binder, the process of recycling end-of-life tyres, EOLTs, which after bead-breaking and processing, are reduced to a new type of tyre:

- slipped used for the production of thermal energy;

- granulate used in cold moulding or to create resin binders;

- Micronized and pulverized are used as additives, reinserted in the production of new tyres, acoustic insulators and anti-vibration sheaths, and finally in bituminous mixes.

In this regard, for years now there have been consolidated technologies for the packaging of bituminous conglomerate with rubber powder, called Asphalt Rubber, which use two methods: WET and DRY:

In the former the powder, in quantities between 10 and 30% by weight of binder, is inserted into the bitumen in liquid phase, digestion takes place by dissolution.

In the second, on the other hand, powder and granulate are inserted in quantities between 1 and 3% by weight of the aggregate in the form of the latter, a technology that has not been very successful compared to the wet method due to the reduced phenomenon of interaction with bitumen. In fact, the powder tends to absorb the aromatic part of the binder, favouring the phenomenon of shelling.

The study presented focused its theoretical-experimental actions, therefore, on the re-use of ELTs in the form of powder which, combined with waste oils from the food chain and additives of natural origin, made it possible to develop a road pavement binder of the “bio-binder” class, an encouraging substitute for a traditional bitumen. It is a free bitumen binder with the same performance characteristics typical of a bituminous binder.

Considering all the positive aspects of introducing rubber powder into bituminous mixtures, a valid alternative to the latter has been sought using natural substances, each with a specific task:

- The polymer SBS (Styrene-Butadiene-Styrene) is a macromolecule that gives elasticity to the binder;

SBS polymer

- rosin acts as a binder between the elements, and is a solid residue of the distillation of different conifers in order to obtain turpentine essence;

Rosin

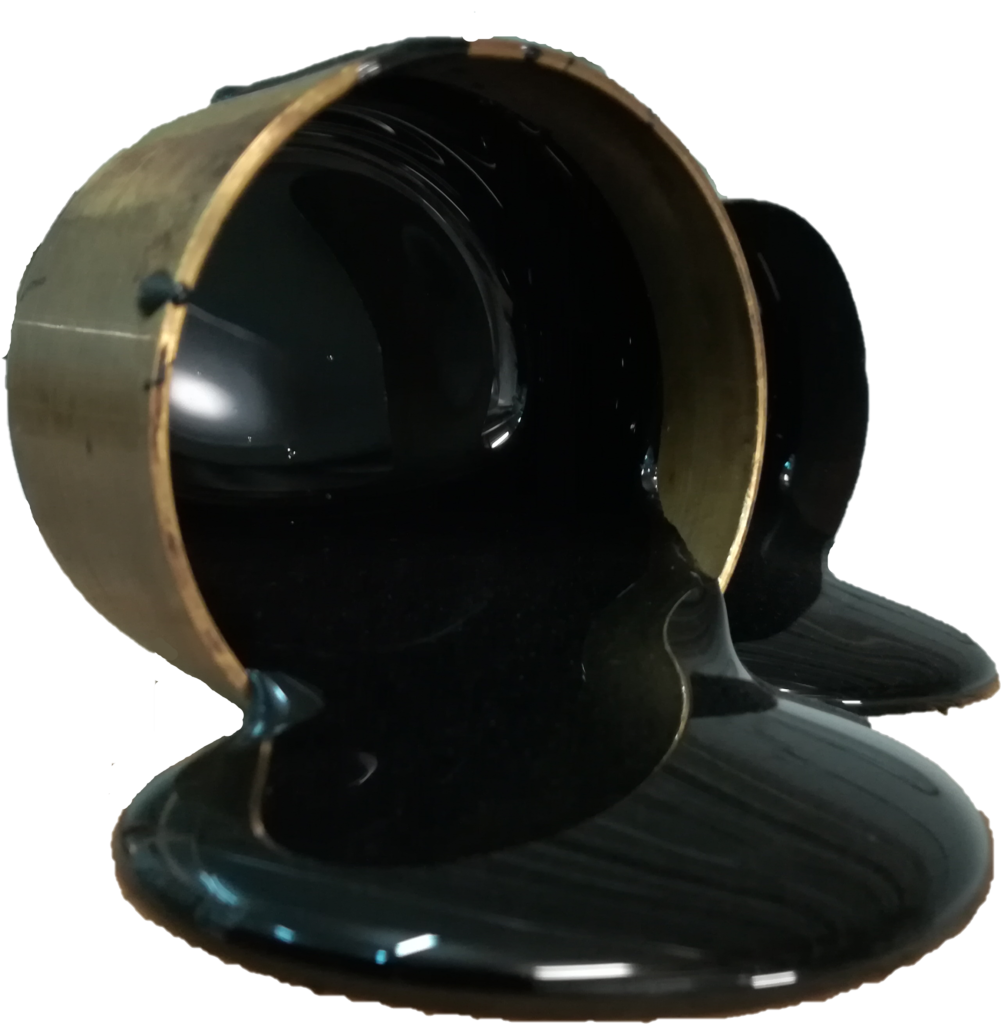

- the spent seed or olive oil makes the compound more fluid, making it easier to prepare and mix;

Oil

- rubber, a low cost elastomer, gives elastic behaviour to the compound, reduces the possibility of permanent deformation and gives longevity to the mixture;

Rubber

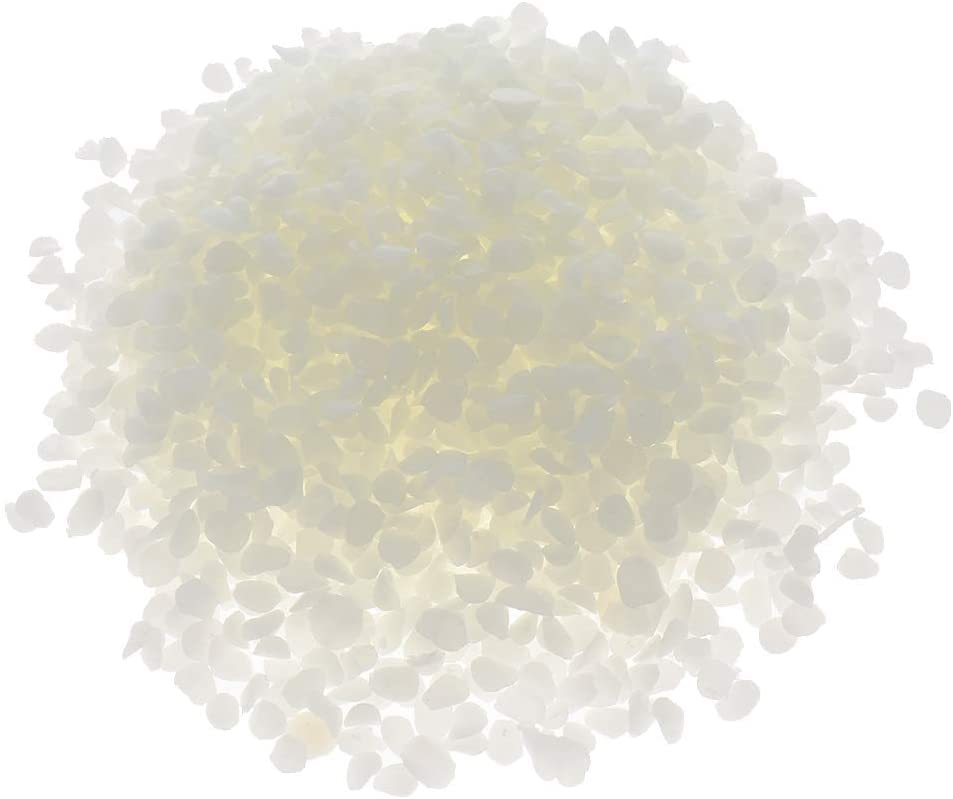

- the wax pearls correct the fluidity of the compound, and finally…

Wax pearls

- the viscosifier useful, depending on the proportions of the other components, to correct the viscosity of the compound.

Guamm Viscosifier

The formulations were 12, each one characterized by different weight ratios of the different components, therefore, by a different percentage of pfu powder, remaining within the regulatory limits of 10%÷30%. Each mixture sampled underwent an immediate analysis that made it possible to define, with an initial visual and tactile survey, the behaviour of the blends: it was noted that in relation to the type of exhausted oil used, the samples were found to be:

- With seed oil, turbid, granular and not very elastic;

- With olive oil, on the other hand, glossy, well homogenised, therefore smooth and deformable.

For the rheological characterization, the mixtures were analysed at the RSD useful for the evaluation of the viscoelastic behaviour of the material at varying temperatures.

- The elastic modulus G’ is the part in phase, and is the reversible measure of the stored elastic energy.

- The viscous modulus G” is, instead, the out-of-phase component, and represents the irreversible viscous dissipation.

Their ratio represents the delta tangent which defines the transition of the compound from gel to liquid as the temperature increases.

RESULTS OBTAINED

In order to be able to make a comparison of mechanical performance, mixtures with a small percentage of bitumen and mixtures totally purged from it have been made.

Blends made and chosen for the physical-mechanical characterization.

According to the results obtained, the E4′ and E7′ free bitumen blends have surprisingly superior mechanical characteristics to the E4′ and E7′ bituminous blends. This behaviour highlights the ability of the eco components to impart binder-like characteristics superior to the bitumen itself.

Once the blend with the highest rheological performance was chosen, it was used for the packaging of standard size cylindrical samples of bituminous conglomerate with carefully selected aggregates, which were then subjected to a study of the physical-mechanical characteristics.

Once mixed, they were constipated using the Marshall method and then evaluated for Stability and Marshall Running at 60°C, Indirect tensile strength to sample breakage at 25°C and void content.

CONCLUSIONS

The results obtained show that the Stability of cgb E7 is equal to the acceptance of a special tender specification of 11 KN, and in fact the cgb as such has a Marshall stability of just above, only 2 KN.

Marshall Stability and Sliding Test (60°C)

Indirect traction resistance up to breakage (25°C)

The fact is that the two stiffnesses are higher than those expected in the specifications, respectively 70 and 47%, but in fact today with modern bitumens these values can be found in building site practice, where bitumens from refineries provide strength and stiffness that are in agreement with the results obtained and higher than the specifications.

The study presented showed promising performance for the biobinder investigated:

- stable in terms of Marshall Resistance;

- capable of good volumetric attitudes in terms of internal void content.

Future research developments invite the need to improve the aspects closely related to the inert binding.